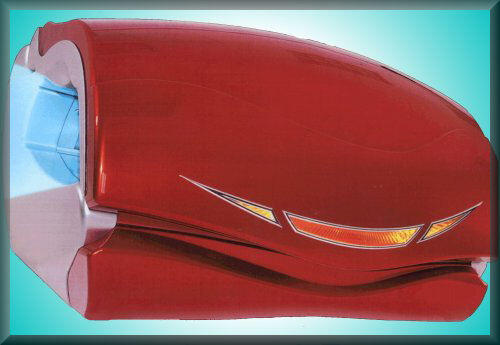

Arrowhead has a 40-year history of custom fiberglass fabrication and a wide variety of thermoset materials for a vast number of industries. Inexpensive tooling, Engineering and Design support, a wide variety of new composite materials and a large selection of composite molding processes provide Arrowhead\’s staff with a unique capability to manufacture high-quality fiberglass and plastic products for a variety of different industries.

Fiberglass closed molding processes like Resin Transfer Molding (RTM), RTM Lite, Closed Cavity Bag Molding (CCBM), and Sheet Molding Compound (SMC) provide Arrowhead with multiple options for assisting all types of companies who need parts with a smooth finish on both sides, a controlled wall thickness, and/or high volume requirements. Arrowhead’s fiberglass spray-up molding and fiberglass hand lay-up molding capabilities are proven processes for extremely large fiberglass parts, lower volume parts, or parts that require molded-in inserts. All of these processes can be used to mold fiberglass parts with compound curves, molded-in color, high strength to weight ratios, a paintable surface and all use cost-effective tooling. Most fiberglass-molded products also meet the FMVSS 302 flammability standard.