Whether your part will be made from molded fiberglass or thermoformed plastic, Arrowhead can help you with the product’s development from concept to production and everything in between. Sometimes it’s a sketch on a napkin. Sometimes it’s a sophisticated CAD model. Sometimes it’s a previously produced prototype. Regardless of where you are in the product design process, Arrowhead is here to help.

Engaging with Arrowhead in the beginning stages of the fiberglass or molded plastic product development process is ideal. I have been witness to way too many fiberglass and plastic products with a beautiful design that cannot be easily produced. As a custom fiberglass molder and heavy gauge thermoformer, we know all too well the pitfalls of poor part design. Poor part design can result in parts that are hard to manufacture, difficult to replicate, may not meet the intended project parameters and ultimately, expensive to produce. Involving Arrowhead at the beginning of the part design process is always recommended and can often times save money and headaches.

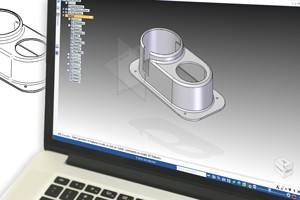

The end result of the design process for a thermoformed plastic or molded fiberglass part is usually a CAD model, print or hand sculpted prototype. Although Arrowhead prefers that our customers provide the print or CAD model (with design input from Arrowhead), we can assist with the generation of these if necessary.

If a print has been drawn up, often times it is best to convert that print into a CAD model to ensure accuracy to the original design. If a prototype part has already been made, sometimes it is possible to make tooling off that prototype (though we generally don’t recommend doing this) or, thanks to Arrowhead investing in a FARO arm, a laser scan can be made of the prototype. This laser scan can then be turned into a CAD model. A CAD model will allow Arrowhead to cut a temporary mold or pattern that can be used to make prototypes or production tooling.

Once the pattern has been made, Arrowhead is able to check for dimensional accuracy (if necessary) by utilizing our Renishaw attachment or our FARO arm. After pattern dimensions are found to be within tolerance, prototypes of your fiberglass or thermoformed plastic part can be made from the pattern. There is always the chance of damage to the pattern when doing this, so we don’t recommend doing this in some situations.

Once prototypes of your fiberglass or thermoformed part have been produced, it is time to make production molds. Just like with every step mentioned above, Arrowhead has the ability to produce production tooling in house. Our proprietary Eco-Tooling technology has been a favorite of many of our thermoforming customers for many years In house tooling helps ensure lead times are met, issues are addressed immediately and changes can be made expeditiously.

In addition to production molds, Arrowhead also produces production routing jigs, CNC nests, gluing fixtures and various other auxiliary fixturing necessary to produce your part. Since 99% of the time we are the ones that will ultimately be making our customer’s parts, we produce fixturing we know will be easy to use, functional, cost-effective and precise. We also have multiple CNCs available to trim your parts if that level of sophistication and precision is necessary. Like everything else we utilize CNCs for, we program our own CNCs for trimming operations. We are able to do both offline programming and programming with a teach pendant which is crucial for parts who don’t have a CAD model associated with them.

After production fixturing and molds have been produced, it is time to produce a production part. Just like the other steps mentioned above, Arrowhead is able to mold your thermoformed and/or fiberglass parts on a production basis. We have numerous pieces of equipment and highly trained personnel at both our fiberglass molding facility and our thermoforming facility that ensure we are producing your parts in a timely manner and at a level of quality that meets or exceeds your expectations.

As you can see, Arrowhead can be a one stop shop for all of your custom fiberglass molding and thermoformed part needs. We want to do everything we we can to help you mold your ideas into reality.

Call me to talk about your next project and let Arrowhead do our part to help that new project be a success from concept to production.