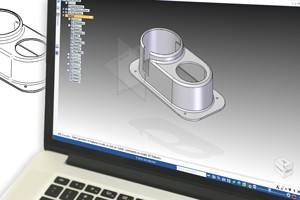

At Arrowhead, we offer expert plastic part CAD services to ensure every component we manufacture meets precise design and functional requirements. Computer-Aided Design (CAD) is essential to achieving the accuracy and repeatability needed in modern plastic part production. Through advanced 3D modeling, we provide a virtual representation of your part that allows both our engineering team and you—the client—to evaluate the final form, fit, and function before any material is formed.

Our CAD services include both 3D and 2D capabilities. While 3D models give a detailed preview of how the plastic part will perform in real-world conditions, 2D drawings deliver the critical dimensions and specifications needed to meet industry and application standards. These design tools are vital for identifying potential challenges early, reducing costs, and improving production efficiency.

Arrowhead’s CAD support is tailored for custom fiberglass and thermoformed plastic parts. Whether you need help converting legacy files, generating new part models, or rebuilding geometry from existing components, our experienced engineers work closely with you to deliver accurate, production-ready designs.

With our focus on quality, detail, and collaboration, our plastic part CAD services ensure your parts are designed with manufacturing in mind—right from the start. Contact us to discuss your next plastic parts and components project.

Let’s Talk About Whether SRTM is Right for Your Part

Silicone membrane resin transfer molding (SRTM) offers a clean, consistent way to produce fiberglass parts with less mess and more repeatability. At Arrowhead, we can help you determine whether SRTM or another fiberglass molding process is the best fit based on your part geometry, production volume, and finish requirements.

We also offer full trimming and finishing support with 5-axis CNC trimming to bring your part from mold to final spec.

Have a fiberglass part that might be a fit for SRTM?

Contact us today to get started.